For far too long, I was dedicated to the pour-over. At some point, I decided that I had sufficient time in the morning to boil water and then stand over a Chemex for many, many precious minutes because, dammit, this is better.

Two children who are running perpetually late for the bus and four broken Chemexes later, I can officially say that, sure, the coffee is a lot better, but ain’t no one got the time or money for that shit. It’s why I went back to drip coffee and haven’t looked back.

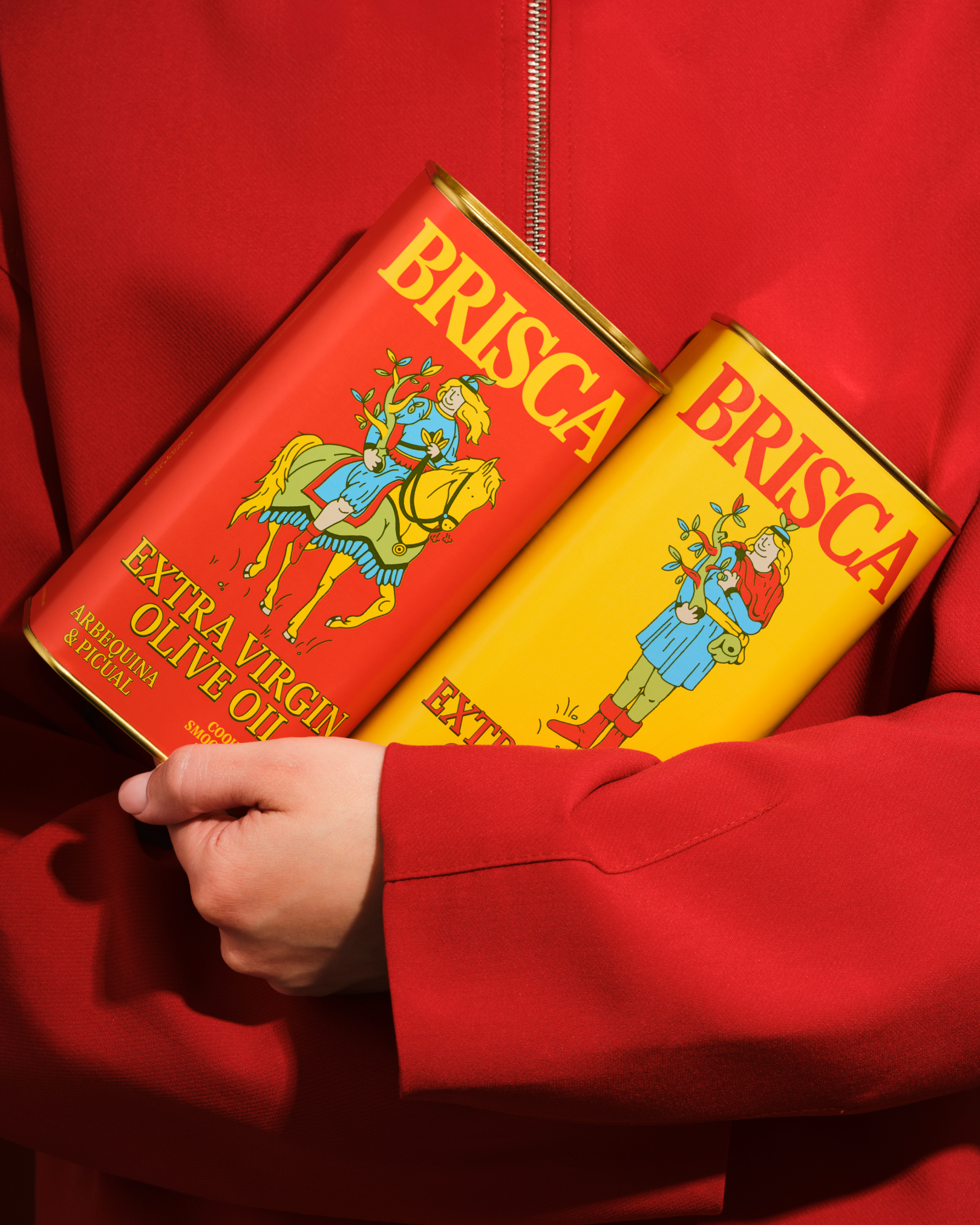

Well, OK. Kind of. While I didn’t want to drop another 50 bucks on a piece of glass I would inevitably break once again, I recently got my hands on one of our DIELINE Awards winners, the Dwell Dripper from Verve Coffee Roasters. This little guy is made from silicon, and when I’m feeling fancy on the weekends, I’ll treat myself to a single-serve. What really drew me in, however, was the packaging, and I’d even argue that Zenpack quietly created one of the best pieces of packaging we saw last year. Not only is the packaging plastic-free, but it also offers the perfect display to showcase the product, while doing away with extraneous packaging fillers to protect it. It’s the rare container that effortlessly becomes a canvas for something bigger.

Oh, and it has a handle. Who doesn’t love a handle?

I spoke with Leo Chao of Zenpack about how they brewed up the packaging for Dwell Dripper and what other CPG categories could benefit from using just cardboard.

What was the brief that you got from Verve Coffee for the dripper?

Verve came to us with a clear but challenging brief: this was their first-ever brewing device, so the packaging had to do more than protect it. They asked us to create something to give the Dwell Dripper a strong retail presence, showcase its design and multiple colorways, and integrate the matching scoop into the unboxing experience. At the same time, the solution needed to be cost-efficient to produce, sustainable, and recyclable, while still protecting the product during transit. In short, they wanted packaging that reflected Verve’s brand values and made the Dwell Dripper feel like a complete, elevated product launch.

I would argue that this is the best dieline of all our 2025 winners. How complicated was it to nail this one?

The driving concept came from some familiar shopping bag forms. We knew we wanted to create something with a handle that invites people to pick it up and immediately feel a connection with the product.

From there, the dieline really evolved—we went through multiple iterations to find the right balance between packaging integrity, product reveal, and graphic design space. Structurally, it was a bit complicated, but the real challenge was ensuring it could be kitted efficiently while still expressing our design intention. We designed a single-part dieline that folds into a triangular structure, includes a dedicated compartment for the scoop, and flattens for efficient shipping. That mix of usability, sustainability, and visual presence took time to perfect, but it’s what makes the dripper packaging so successful. As I write this, I realize how complicated it is, but honestly, we had a lot of fun tackling these challenges—the evolution felt natural.

How did you ensure that the scoop would be secure in the packaging?

There’s a bit of a story behind the scoop—we actually product-designed it for Verve.

Because we were responsible for both the scoop and the packaging, we had the luxury of ensuring it matched the footprint of the dripper from the start. That alignment made things much easier when we created a dedicated compartment underneath the main platform. From there, it was just a matter of adding a simple stopper to secure the scoop firmly in place while making it easy for customers to access.

Obviously, the coffee dripper is made from silicon, so there’s no fear of breakage. But we loved the plastic-free nature of the packaging and how you can not only carry it with the handle but also protect it during transport without any extraneous fillers or foams. What else might a piece of packaging similar to Dwell’s be applied to?

It makes us so happy when others recognize the plastic-free design. We’ve taken pride in setting this as a goal for all the projects we work on.

I see a lot of potential for this design. Structurally speaking, we created a shallow cavity that allows the product to sit securely, and then added a paper-clamshell structure to encapsulate it. It could be applied to kitchenware, stationery, and wellness accessories. I think it’s especially useful for products that need a retail-ready display, an integrated handle, and a protective structure.

Recently, we had the chance to apply this concept to a very fragile glass and ceramic product, and it passed ISTA testing—so we believe it has the potential to become a strong solution for many more applications.

Is there any specific category of CPG packaging you wish you could redesign? Why?

We’re lucky to work with clients across various industries, but if I had to pick one category, it would be toys. As the dad of a 7-year-old, I’ve had way too many late nights wrestling with plastic clamshells and endless twist ties—sometimes it feels harder to unbox the toy than to play with it. The toy aisle is tough because shelf visibility and margins drive most choices, but I think there’s a big opportunity to rethink the system. Imagine toy packaging that’s just as fun to open as the toy itself—and completely plastic-free.